Having a sturdy shed floor is crucial to maximizing the life of your shed. If the construction is not done properly, a multitude of problems will and can occur over the life of your shed. Here are just a few:

- Initial construction will be harder for the rest of your shed if you don't build the floor right.

- Door can become warped.

- Windows can leak.

- Roofs can leak.

- Dangerous conditions will continue to crop up.

There is more than one way to build a shed floor and this is how I build my wooden shed floors.

The following instructions refer to different terms like band boards, rim joists, floor joists, and skids. If you are unsure of what those terms are please have a look a my shed floors page.

1. Check your local building codes if you haven't already to determine what type of anchoring you need to do for your shed.

When building your shed floor its a great idea to check your local building codes.

Chances are if you have applied for a permit you'll know the answer to this question already. Usually, there are two types of anchoring if you are not building on top of a concrete slab. One way is to anchor your shed to the ground using cable tie-downs, or anchoring it with your floor being fastened securely to posts which are sunk into the ground at a pre-determined depth in concrete.

Make sure whatever is required by your county that you follow their guidelines.

2. Gather the proper lumber to cut your floor joists, rim joists, and 2 two band boards and 4x4 skids. Cut all floor joists to proper length along with your 2 rim joists and two band boards and skids. Also, cut your 4"x 4" skids to length.

3. After cutting all lumber, mark off your two band boards for joist layout at 12" on center. Assemble the frame using 16d galvanized common nails, making sure to check each joist for crowning and install it with the crowned edge up.

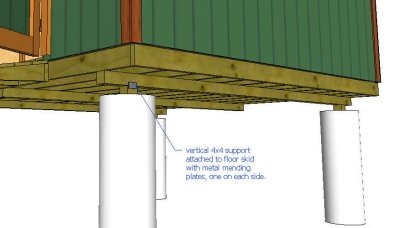

Building your shed floor on skids.

4. Lay out your 4" x 4" skids properly spaced and lined up on your foundation, making sure they are level. Set the floor frame on top of the skids and measure the diagonals to make sure it's square. At this point, toe nail all joists to your skids using 16d common nails. The joists which fall at the 4', 8', and 12' lengths along your skids should be measured before nailing to make sure they are nailed exactly on center at those distances. This way,

when laying your decking down, your edges will fall right in the middle of your joists for easy nailing.

5. Whichever method you need to use for anchoring your shed should be done at this step before laying down and nailing your floor sheathing.

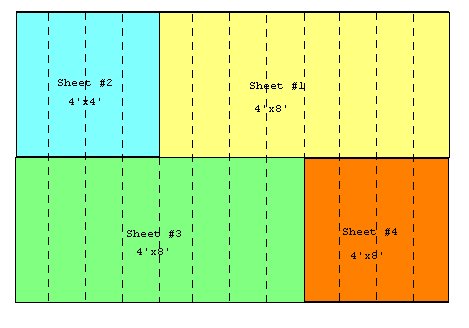

Stagger your floor sheeting when building your shed floor.

6. Now lay out your floor sheeting starting with one of the front corners first. The reason for this is that you want the front part of your floor looking nice. It's the first thing visitors will see when stepping into your beautiful new shed. Use 8d galvanized box nails driven every 6" along the edges and every 12" in the field.

Adding a ramp to your shed floor.

It's easy to add a ramp to your shed floor. Many sheds will serve the purpose of having a place to store riding mowers, 4 wheelers, outdoor equipment, etc. You'll want to build a ramp to make it easier to move these items in and out of your shed.

DISCLAIMER

Do not purchase materials or attempt to build this shed project unless you have studied the information provided thoroughly, and have verified all dimensions and material requirements for yourself. Also verify that the plans conform to local building codes and practices. Although every effort has been made to ensure the accuracy of the information and design, the user is ultimately responsible for the use of this information. All information provided is copyrighted and cannot be duplicated without the permission of Shedking.

Thinking about a concrete shed floor?

More information about how to build a shed.

Original article and pictures take http://www.shedking.net/shed-floor.html site

Комментариев нет:

Отправить комментарий